GLOBAL VACUUM TEST

Do you have any question ?

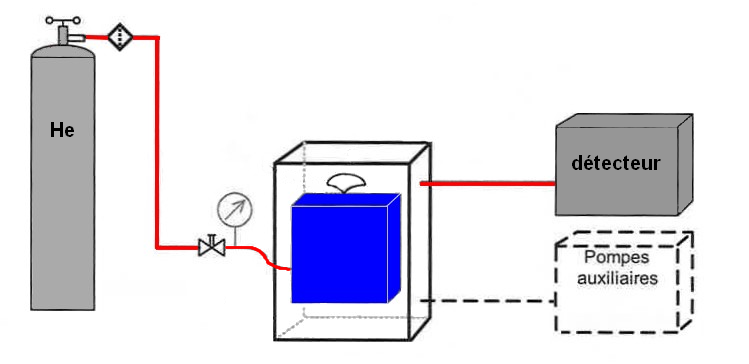

The global test is used to know the possible total leakage of the part.

Localization is not an option with this test.

OPERATION:

a) A part is inserted inside a vacuum chamber

b) A detector is connected and linked directly to the chamber

c) The chamber is pumped out via a pump (s)

d) The part contained in the chamber is emptied of its air and then pressurized with helium

e) The part lets the helium escape into a vacuum through any leaks

f) The detector quantifies helium leaks in the vacuum chamber

Examples of realizations of vacuum machines :

BEA studies tightness control machines according to customer needs and requirements (air conditioning condensers, heat exchangers, etc.).

It is possible to realize a double chamber detection machine allowing the loading of one chamber while the control of the other.

The control of two parts simultaneously in the same room is also possible to gain in productivity.

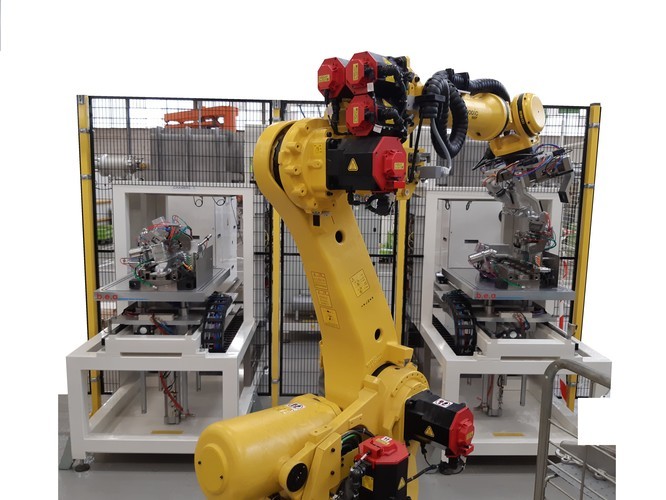

The checking machine is loaded manually or robotically.

Robotic helium leak testing machine for water CAC (Charge Air Cooling: cooling air / turbo exchangers for automobile engines).

• Automatic loading of parts by a robot

• Automatic part capping (20 connection points)

• 3 circuits internal to the part tested in the same cycle

• Marking of good parts

Automatic Helium Leak Testing Vacuum Machine for Car Radiators

• Allows loading by robot or operator

• Automatic part connection

• Wide range of sensitivity: from 1.10-5 atm.cm3 / s to 0.1 atm.cm3 / s

• Integrated helium mixer and analyzer

• Adjustable test pressure and leak rate

• Traceability of test results

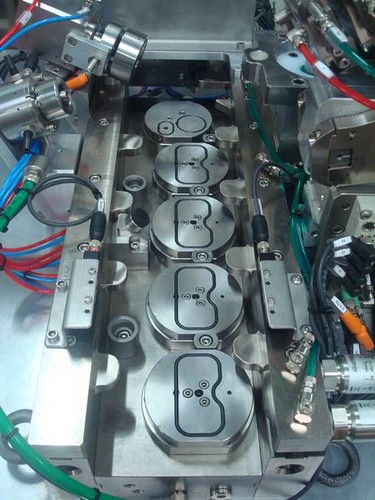

Automatic tools for leak detector, automotive sector

The tools complement the waterproofing control machines. We make tools such as:

- Helium leak detector tooling for automotive heat exchangers

- Helium sealing control tool for vehicle air conditioning condensers